- For PC

- For MAC

- For Linux

- OS: Windows 10 (64 bit)

- Processor: Dual-Core 2.2 GHz

- Memory: 4GB

- Video Card: DirectX 11 level video card: AMD Radeon 77XX / NVIDIA GeForce GTX 660. The minimum supported resolution for the game is 720p.

- Network: Broadband Internet connection

- Hard Drive: 23.1 GB (Minimal client)

- OS: Windows 10/11 (64 bit)

- Processor: Intel Core i5 or Ryzen 5 3600 and better

- Memory: 16 GB and more

- Video Card: DirectX 11 level video card or higher and drivers: Nvidia GeForce 1060 and higher, Radeon RX 570 and higher

- Network: Broadband Internet connection

- Hard Drive: 75.9 GB (Full client)

- OS: Mac OS Big Sur 11.0 or newer

- Processor: Core i5, minimum 2.2GHz (Intel Xeon is not supported)

- Memory: 6 GB

- Video Card: Intel Iris Pro 5200 (Mac), or analog from AMD/Nvidia for Mac. Minimum supported resolution for the game is 720p with Metal support.

- Network: Broadband Internet connection

- Hard Drive: 22.1 GB (Minimal client)

- OS: Mac OS Big Sur 11.0 or newer

- Processor: Core i7 (Intel Xeon is not supported)

- Memory: 8 GB

- Video Card: Radeon Vega II or higher with Metal support.

- Network: Broadband Internet connection

- Hard Drive: 62.2 GB (Full client)

- OS: Most modern 64bit Linux distributions

- Processor: Dual-Core 2.4 GHz

- Memory: 4 GB

- Video Card: NVIDIA 660 with latest proprietary drivers (not older than 6 months) / similar AMD with latest proprietary drivers (not older than 6 months; the minimum supported resolution for the game is 720p) with Vulkan support.

- Network: Broadband Internet connection

- Hard Drive: 22.1 GB (Minimal client)

- OS: Ubuntu 20.04 64bit

- Processor: Intel Core i7

- Memory: 16 GB

- Video Card: NVIDIA 1060 with latest proprietary drivers (not older than 6 months) / similar AMD (Radeon RX 570) with latest proprietary drivers (not older than 6 months) with Vulkan support.

- Network: Broadband Internet connection

- Hard Drive: 62.2 GB (Full client)

Our colleague Clay Remy told us a story about his visit to the Minnesota Military Museum, his measurements of armor and dimensions of some of the vehicles, and about upcoming changes to the gaming models we created after his trip.

The Museum

Nestled in the heart of Minnesota lies an active duty National Guard base that stands as a testament to the ongoing service and sacrifices of the people of Minnesota. I am speaking of course about Camp Ripley and the Minnesota Military Museum.

Located adjacent the small town of Little Falls, (the boyhood home of legendary aviator Charles Lindbergh) the museum’s focus is not merely on the US Military Units and equipment from Camp Ripley itself, but the experiences and lives of all Minnesotans from all time periods in service to their State and Country. From rare examples of a very rare and well preserved 75mm Sherman Jumbo all the way up to modern tanks and SuperCobra attack helicopters. When we first contacted the Museum about coming there to study some of their vehicles, their Administration was immediately excited and ready to receive us and gave us their full support. Their knowledgeable and friendly staff such as Curator - Doug Thompson whose own Grandfather served with the 5th Marines at Belleau Wood, as well as all the other very friendly and dedicated staff, provided us with unlimited access and assistance throughout my stay at their facility and during our entire study.

M60 tank series

In an effort to continuously develop the most accurate machines of battle possible and also to verify existing models and or information from historical documents that can often conflict from various sources over extensive time or service periods. It can be often be necessary to directly study such vehicles and directly measure using multiple methods in order to compare that information to archive documents obtained from primary sources. This allows for a clear picture (similar to getting a CT scan but for tanks) of a real tank in the field that can then be compared against the in game model in order to make adjustments if needed (physical data+archived to virtual).

The training turret allowed us to study not only thickness and structure in several ways not possible on a service turret but also internal layout and geometry. Most prominently because training turrets have large sectioned holes in the sides that the instructor (in tank school) would stand on a platform and give the tank crew commands and instruction through as well as complete access to the base without the interference of the barbette. This allowed us to take extremely precise measurements of the turrets complete profile, as well as to measure certain parts of the armor casting and internal components not normally possible before without having internal access to the crew compartment.

M1 “Abrams”

The M1 Abrams at the Minnesota Military Museum has a history as unique as the museum itself. Originally one of the first 110 Abrams produced and built by Chrysler defense before the General Dynamics took over, this tank served at Aberdeen proving grounds as one of the many testing vehicles there during M1 development and improvement projects for the M1, M1IP, and M1A1 series of tanks which occurred nearly simultaneously during that timespan and were known as X-M1(LRIP) (low rate initial production). Consequently, after the M1 improvement program produced the M1IP, and M1A1, this tank was then donated and transported to where it now sits in a well-preserved manner. Thanks to the dedicated museum staff and ongoing support from the National Guard units at Camp Ripley that continue to look after all vehicles at the site etc, routinely.

This tank upon first glance you will see it shares the standard turret of the first production M1 along with the 105mm M68 Cannon. However, the rear side skirt, as well as the reinforced front suspension and lack of retainer ring on the rear drive sprocket from the M1IP program, are also in place.Taking the documents on the M1 Abrams that were available, and comparing them to the real tank’s construction and geometry in order to not only verify the data used for our in-game model (and pretty much every Abrams tank in every other game as official publications are extremely limited) but also to fill in the gaps of that information where needed so that we could improve where possible.

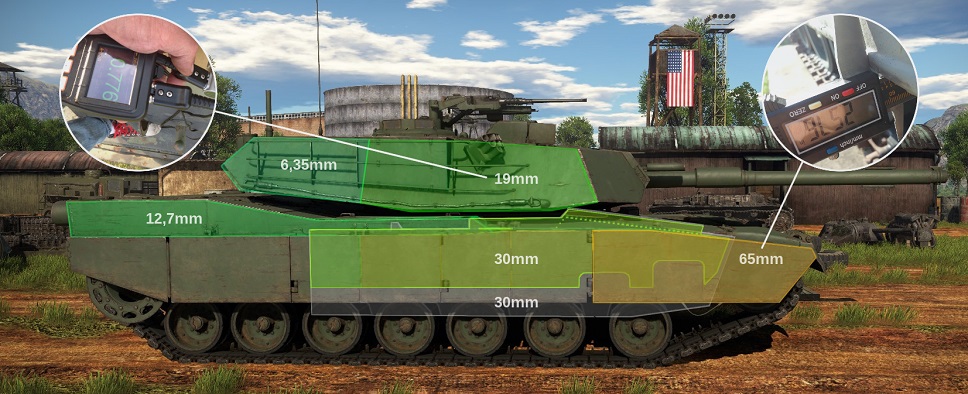

Beginning with the Chassis and hull we began checking the armor in the side skirts ensuring not only their overall thickness (65mm) but also the individual thicknesses of each layer (38 mm of special armor with a 1 inch thick outer plate).

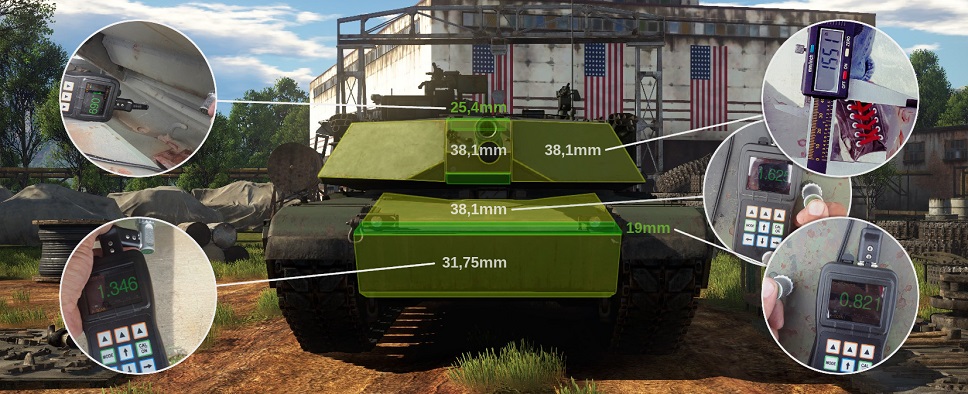

We began the geometric and thickness scan of the entire hull working from the side armor with its 30mm’ sidewalls and additional 30mm plates that are welded mostly flush but in some areas with a small (1/16’' to 1/4’') air gap to the hull side allowing for a flat surface against the road wheels so that debris does not become wedged inside of the space. The frontal hull (lower glacial) we were able to measure precisely from the lower hull plate all the way to the upper glacial in order to determine that both plates are indeed 31mm. Which means that the in-game models lower plate will now be adjusted at its lowest portion where it fuses to the hull from the previous value of 25.4mm to 31mm as noted in the document and as verified on the actual tank. The very lower plate which connects the lower glacial to the hull was indeed 22 inches from front to back demonstrating the positioning rear cavity for the front armor. However, on the sides at the weld seam with the hull is located the mounting bulges for the rear conventional 101mm RHA plate which was visually distinguishable in the design was also clearly available to us allowing us to appropriately verify that we indeed had the lower front assembly on the in-game model correctly positioned as according to the design document and the physical layout on the tank.

We continued the same pattern of study as we moved to the turret, moving panel by panel and piece by piece, measuring via ultrasonic gauges, magnetic non-linear rulers, calipers, and photo telemetrics. The face of the turret was as expected 1.5 inches thick at its outer surface with variances here and there due to the two layers of paint (one inside the cavity and one outside) Locating the rear plate is possible on the turret as well similarly to how the front hull plate is done by locating the mount for it. In the case of front and side inner turret plates, this occurs at the left/right front corners on the underside of the turret approximately 19.5” front the front face of the turret (total size of cavity for the special armor in turret front) and 12.5” to the side wall of the turret (total size of the special armor cavity in turret side). Comparing to the in-game model, known data, and documents. We again found that our model matched the physical tank and no adjustment was necessary in this department. This continued for the rest of the time we spent on this tank and every square inch until we ran out of time and ran for the airport. Getting hands-on results, of course, your ability to get very precise structural information that is sometimes not so clear due to lack of official records thanks to the measurements, geometric and photometric detailing, as well as ultrasonic testing. We were able to verify the core components, armor, and structural makeup of the in-game model M1 Abrams confirmed to the NARA and CIA documents as well as the Minnesota M1 Abrams (chassis modifications aside) as most exhaustingly could be determined during this trip. Not that our investigations ever stop either, and we always welcome your input.

The War Thunder Team

Comments (94)

Is there a possibility of the Abrams getting a lower repair cost? Currently the type 90, Leopard 2A4, and Challenger all share a repair cost of less than 7,000 silver lions, but the Abrams both cost over 14,000 to repair.

Ummm, buddy when was the last time you looked at the challenger's repair cost, cause that bad boy is at 18 000, (i think its the most expensive one in the game), as a side note, repair costs really do need to become standardize by tier or Br, cause the T-80B costing about 6.6k is abit ridiculous when the Challenger is 3x that.

D3imos, Challengers used to be super expensive until a few months back. Now it's at about 9k spaded.

Gaijin always amazes me with these kind of effort they put into modelling these modern tanks and being very transparent with their findings. It is very much appreciated. I hope in the future you can go to Bovington Tank museum to do similar things with the tanks there like the Challenger seeing as they're currently modelling the Challenger with MBT-80's data.

https://warthunder.com/en/news/5645-datasheet-challenger-historical-references-en ?

I cannot approve until they fix the left mg on both abramses. They lack the ammo box..

Great work. Visit Japan next! Japanese tech tree really need some love. :)

no

SXTREME, i agree with this man SXTREME

So did you finally fix the M60's mantlet?

We will see ;) I did spend collectively about (approx) 2 days or so all over, inside, (and somehow in between some uncomfortable places) In order to give the M60 series tanks the best credit she is due.

FryingTigerWT, you are the best :)

Hell yeah, they went to my second home and backyard/playground. Minnesota National Guard all the way!

Now they can go to Kubinka and collect information about the Zrinyi , Turán.. etc.

Dont forget the Italian and the Romanian tanks

Dolokhov, Yep we need an those vehicles :D

now you need to fix other things like, i dunno, matching Germany with America as a team?

sheeesh, *sarcastically* I love playing Leo from WESTERN Germany against US/UK and EASTERN T-54s etc. :D *sarcastically*

This mechanic is dumb. Why can't we be unrealistic and at least allow Germany to fight with Nato as they do historically. At least at top tier. It does not affect balance. USSR can hold its own vs Germany and the US.

Great work!

So when are you gonna fix the repair cost, for both Abrams?

Yes, no sekrit documents this time :D

Submit a complaint