- For PC

- For MAC

- For Linux

- OS: Windows 10 (64 bit)

- Processor: Dual-Core 2.2 GHz

- Memory: 4GB

- Video Card: DirectX 11 level video card: AMD Radeon 77XX / NVIDIA GeForce GTX 660. The minimum supported resolution for the game is 720p.

- Network: Broadband Internet connection

- Hard Drive: 23.1 GB (Minimal client)

- OS: Windows 10/11 (64 bit)

- Processor: Intel Core i5 or Ryzen 5 3600 and better

- Memory: 16 GB and more

- Video Card: DirectX 11 level video card or higher and drivers: Nvidia GeForce 1060 and higher, Radeon RX 570 and higher

- Network: Broadband Internet connection

- Hard Drive: 75.9 GB (Full client)

- OS: Mac OS Big Sur 11.0 or newer

- Processor: Core i5, minimum 2.2GHz (Intel Xeon is not supported)

- Memory: 6 GB

- Video Card: Intel Iris Pro 5200 (Mac), or analog from AMD/Nvidia for Mac. Minimum supported resolution for the game is 720p with Metal support.

- Network: Broadband Internet connection

- Hard Drive: 22.1 GB (Minimal client)

- OS: Mac OS Big Sur 11.0 or newer

- Processor: Core i7 (Intel Xeon is not supported)

- Memory: 8 GB

- Video Card: Radeon Vega II or higher with Metal support.

- Network: Broadband Internet connection

- Hard Drive: 62.2 GB (Full client)

- OS: Most modern 64bit Linux distributions

- Processor: Dual-Core 2.4 GHz

- Memory: 4 GB

- Video Card: NVIDIA 660 with latest proprietary drivers (not older than 6 months) / similar AMD with latest proprietary drivers (not older than 6 months; the minimum supported resolution for the game is 720p) with Vulkan support.

- Network: Broadband Internet connection

- Hard Drive: 22.1 GB (Minimal client)

- OS: Ubuntu 20.04 64bit

- Processor: Intel Core i7

- Memory: 16 GB

- Video Card: NVIDIA 1060 with latest proprietary drivers (not older than 6 months) / similar AMD (Radeon RX 570) with latest proprietary drivers (not older than 6 months) with Vulkan support.

- Network: Broadband Internet connection

- Hard Drive: 62.2 GB (Full client)

Early jet-engined aircraft: The Me 262, and the Yak-15

The concept of the “jet” (stream of liquid or gas propelled through a small area) engine has its origins from two millennia ago, with the first known jet device being the “Hero Engine” - also called aeolipile. Expanding gases from a particular source (in this case boiling water) would be ejected from an angled nozzle, spinning it rapidly and demonstrating an action (gas flow) and a reaction (movement), Newton’s 2nd and 3rd laws of motion. The idea of a contemporary jet engine were in the minds of designers long before the start of World War 2. A jet powered reaction turbine was proposed and patented by John Barber as early as 1791. Turbine machinery that could extract mechanical energy from a gas jet more efficiently was invented 100 years later.

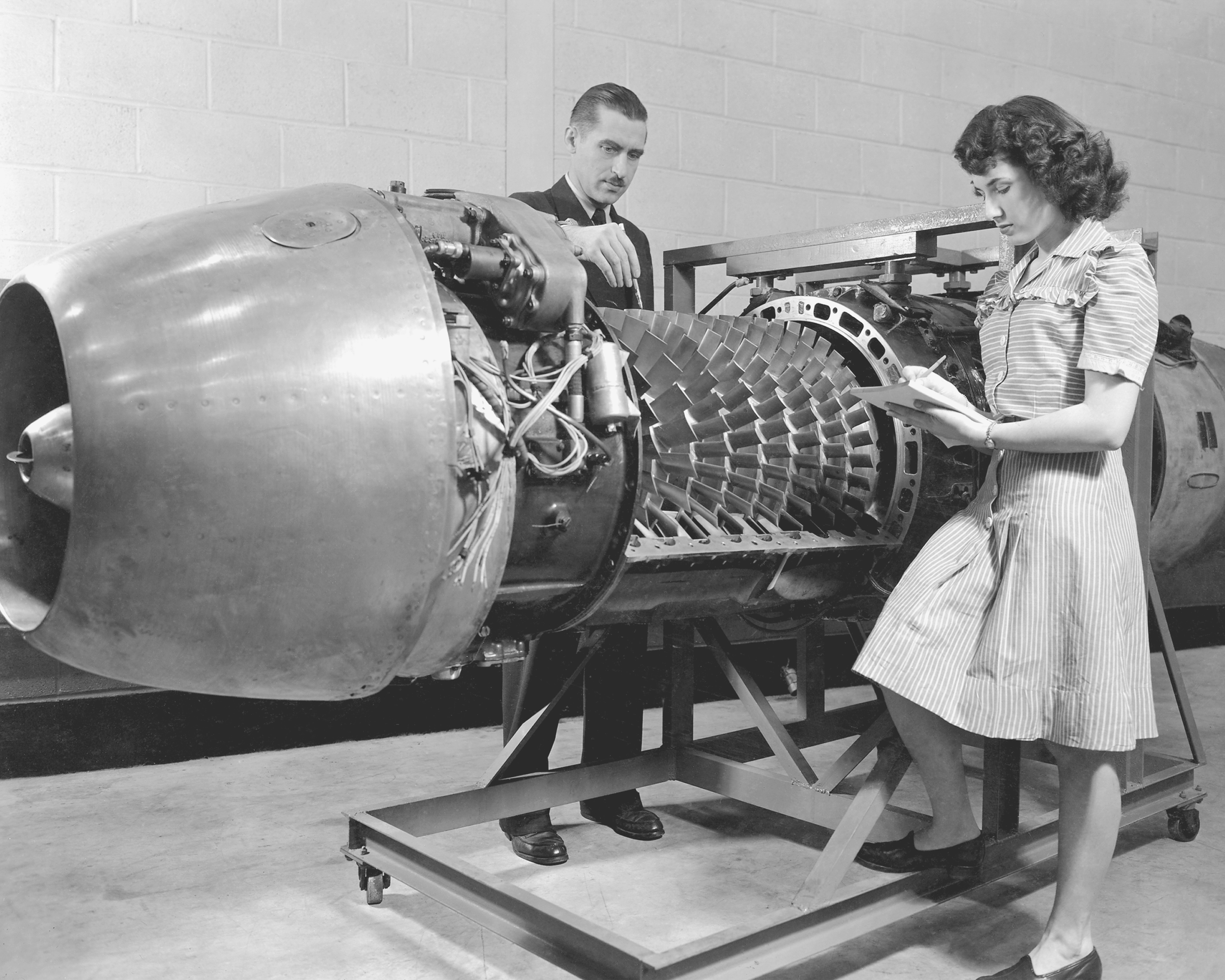

|

| Napier NA357 Compressor wheel |

History can exemplify endless examples in which objects have been moved by jets, and by its “reaction engine” cousin, the rocket, as evidenced in ancient Chinese rocket spears, rocket vehicles and yes, even rocket aircraft - examples being the 1929 Opel RAK.1 and the 1944 Messerschmitt Me 163. In 1910 the Romanian inventor Henri Coandă filed a patent on an aircraft jet propulsion system which consisted of a piston engine driving ducted fan blades: a “motorjet”. The Italian Caproni Campini N.1. was similar, with the addition of an “afterburner” combustion chamber.

The turbo jet engine that we commonly think of today is, in essence, a very simple device. Like a piston engine (Otto cycle), it has a compression, ignition, and expansion stage, the difference being a “continuous open system” allowing a constant flow of matter to travel through it. Thus, all 3 stages run simultaneously, known as the Brayton cycle. Although finding the right air flow and pressure balance was important, the primary reason why it was not applicative until World War 2 was due to a lack of advancement in metallurgy, science, and technology regarding the properties of metal. The exceedingly high centrifugal forces and temperature demands of a turbo jet were at the limits of material engineering of those times, but to some, it was seen as a challenge to be surmounted.

|

| Whittle W.1/W.2B turbojet. Note the large intake impeller on the right. |

Frank Whittle and Hans von Ohain simultaneously and unbeknownst to each other took on the engineering challenge and skepticism of their peers to build working turbojet engines. Although Whittle started tinkering with concepts much earlier and was able to get a working “Whittle Unit” engine 6 months ahead of von Ohain, the latter found more peer support and soon Heinkel was fully funding the development of jet engines for aircraft with the company's top engineers and test equipment, eventually producing the “HeS 3”, which powered the world's first jet aircraft, the He-178. After its first flight on the 27th of August 1939 (4 days before the start of World War 2) official attitudes began to change.

Both Whittle and von Ohain used an “impeller” compressor for the intake air because of its well known and commonplace technology which was used in engine superchargers. Engine turbochargers also existed but were not as common; as did high flow air heaters - in short, their designs used existing concepts in new ways. Both of these designs’ major drawback was their large diameter, which was similar to a radial engine, but while Whittle’s Power Jets W.1 went on to be widely used in numerous variants, the HeS series did not.

|

| Post-war captured Jumo 004. |

Hearing about the new engine, the Junkers company, wanting to make a competing jet, chose Dr. Anselm Franz as chief engineer due to his experience with engine turbochargers and superchargers. Although not very ambitious, his design had a key difference: instead of a large disk impeller, it had multiple rows of fans which forced more air into the combustion chamber. The purpose was to achieve a smaller frontal area, but much more importantly, the engine benefited from an increased airflow through the inlet, resulting in a thrust boost over impeller designs. The resulting Jumo 004 engine powered most early German jet aircraft and pushed the Me-262 faster than early Gloster Meteors, P-80’s, and Soviet jets. The limitations of the new technology, and material shortages, resulted in a relatively short 25 hour lifespan (much like early piston engines) and less thrust than it had the potential to produce. Still, the Jumo 004 gained legendary status and its “axial” design became the foundation of all aircraft jet engines today.

After the war, Dr. Franz travelled to the USA where he eventually settled down and worked for the Lycoming Aircraft Engine department. From his Jumo 004 experience he developed the most popular turboshaft engine in history, the T53 (used in the Bell UH-1 Huey for example). From it came the enlarged T55 and later AGT-1500, the engine that powers the M1 Abrams battle tank!

Author: Joe “Pony51” Kudrna